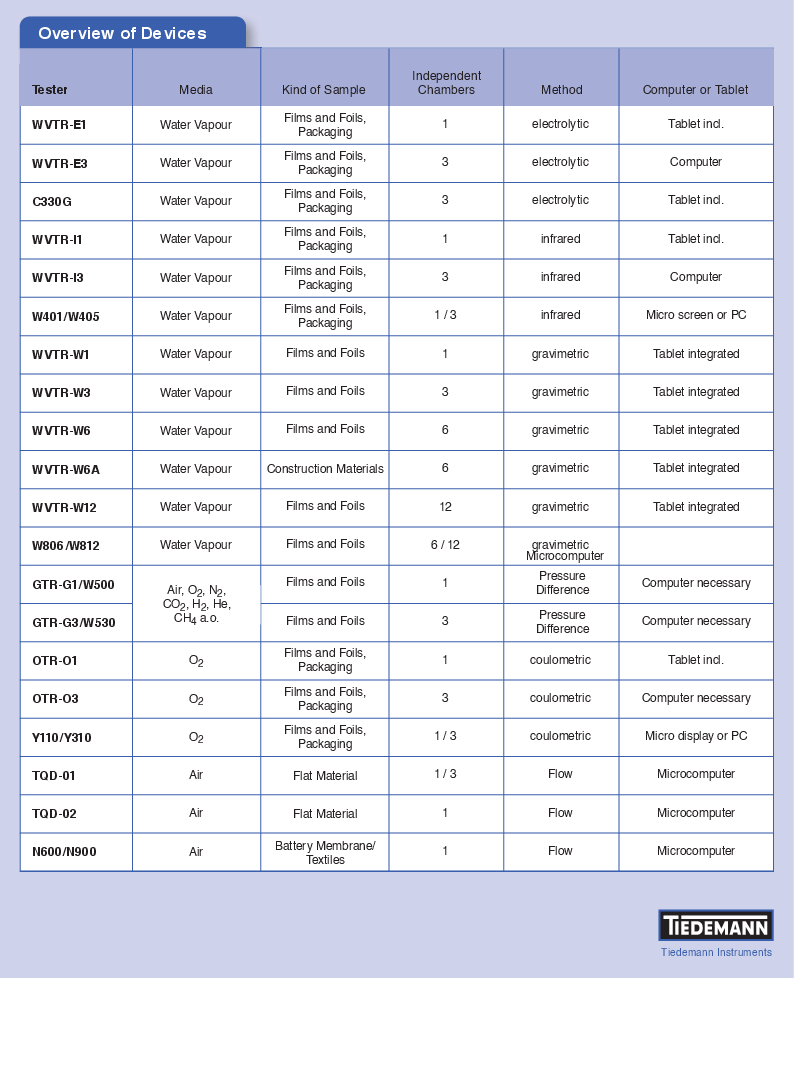

Water Vapour Permeation

With our water vapour permeability testers, the permeation amount of water vapour through a material layer can be measured. The specific ambient temperature and humidity can be set for each test procedure. Depending on the requirements, devices are available for flat packaging materials or finished packaging, as well as different sensors or measuring methods.

The devices for barrier materials WVTR-E1, -E2, C330 are equipped with an electrolytic sensor, the devices WVTR-I1, -I3 and W401, W405 with infrared sensors. These units have integrated software and can test both finished packages and flat material samples.

With the models WVTR-W1, -W3, -W6, -W6A and -W12, as well as W806/812 permeation is determined by weight measurement. The numbers at the end of the designation stand for the number of chambers. The model WVTR-W12 therefore has 12 measuring points.

Electrolytic Method

| Film and Foils | Packaging | |

| Test range | 0.001 – 50 g/m²·24h (Standard) | 0.0001 – 0.25 g/pkg·d |

| Temperature range | 5°C – 95°C | 5°C – 95°C |

| Humidity range | 0%, 35% – 90%, 100% | 0%, 35% – 90%, 100% |

| Standards | ISO 15106-3, GB/T 21529, DIN 53122-2, YBB00092003 | ISO 15106-3, GB/T 21529, DIN 53122-2, YBB00092003 |

| C330G | C330H | |

|---|---|---|

| Test range | 0.00005 – 5 g/m²·24h 0.00000025 – 0,025 g/pkg·24h | 0.005 – 50 g/m²·24h 0.000025 – 0,25 g/pkg·24h |

| Temperature range | 10°C – 55°C | 10°C – 55°C |

| Humidity range | 5% – 90%, 100% | 5% – 90%, 100% |

| Standards | ISO 15106-3, GB/T 21529, YBB 00092003-2015 | ISO 15106-3, GB/T 21529, YBB 00092003-2015 |

Infrared Method

| Films and Foils | Packaging | |

|---|---|---|

| Test range | 0.001 - 50 g/m²·24h (Standard) | 0.0001 - 0.25 g/pkg·d |

| Temperature range | 5°C - 95°C | 5°C - 95°C |

| Humidity range | 0%, 35% – 90%, 100% | 0%, 35% – 90%, 100% |

| Standards | GB/T 26253, GB/T 21529, YBB 00092003, ASTM F1249, ISO 15106-2, TAPPI T557, JIS K7129ISO 15106-3, DIN 53122-2 | GB/T 26253, GB/T 21529, YBB 00092003, ASTM F1249, ISO 15106-2, TAPPI T557, JIS K7129ISO 15106-3, DIN 53122-2 |

| W401 | W403 | |

|---|---|---|

| Test range | 0.001 - 100 g/m2·24h | 0.005 - 500 g/m2·24h |

| Temperature range | 10°C - 45°C | 10°C - 45°C |

| Humidity range | 30% – 90%, 100% | 30% – 90%, 100% |

| Standards | ISO 15106-2, ASTM F1249, GB/T 26253, JIS K7129, YBB 00092003-2015 | ISO 15106-2, ASTM F1249, GB/T 26253, JIS K7129, YBB 00092003-2015 |

Gravimetric Method

WVTR-W1, -W3, -W6, -W6A and W12

Features:

- Full yautomatic tests for dessicant and water method for flat material

- W1: 1 chamber

- W3: 3 independent chambers

- W6: 6 independent chambers

- W6A: ideal for construction material

- W12: 12 independent chambers

- Automatic temperature- and humidity control

- Space-saving control system via tablet

Advantages:

- Value for money

| Test range | 0.1 - 10.000 g/m²·24h |

| Temperature range | 15°C - 55°C |

| Humidity range | 10% - 98% |

| Standards | ISO 2528, GB 1037, GB/T 16928, ASTM E96, ASTM D1653, TAPPI T464, DIN 53122-1, JIS Z0208, YBB 00092003 |

| W812 | W806 | |

|---|---|---|

| Test chambers | 12 | 6 |

| Air movement | 0,5-2,5 m/s | 0,5-2,5 m/s |

| Temperature range | 10°C - 50°C | 10°C - 50°C |

| Humidity range 10% – | 5% – 95% | 5% – 95% |

| Standards | ASTM E96, ASTM D1653, ISO 2528, TAPPI T464, DIN 53122-1, GB 1037, GB/T 16928, YBB 00092003 | ASTM E96, ASTM D1653, ISO 2528, TAPPI T464, DIN 53122-1, GB 1037, GB/T 16928, YBB 00092003 |